Many construction roles are physically demanding which is why it is considered hard work. Every day requires lifting heavy materials and operating dangerous tools while maintaining attention to detail and following a tight schedule. Not to mention all the early mornings and late nights!

So to make it a bit easier for themselves, some workers cut corners. However, that often involves taking up more risk. And the Instagram account ‘Construction Fails‘ is here to remind everyone that there’s a limit to how far you can push these boundaries.

#1 ”not My Job” Awards Goes To ⠀

Image credits: construction.fail

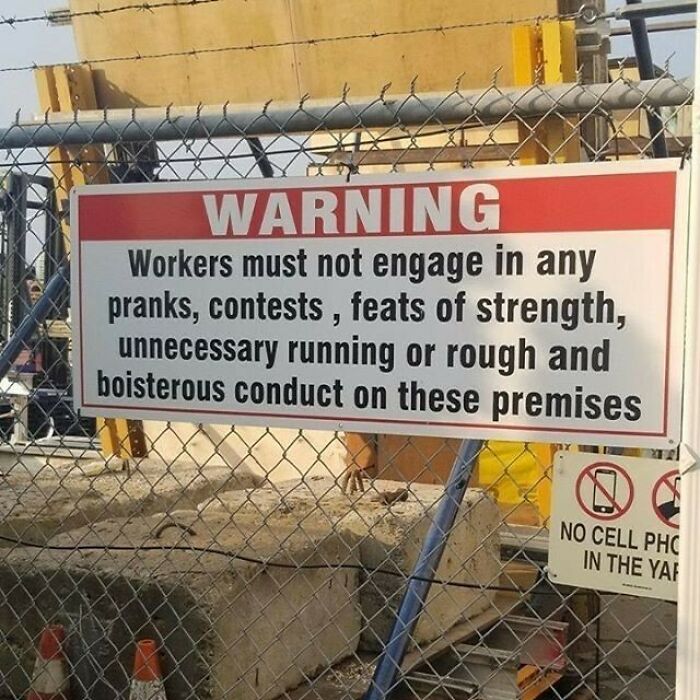

#2 Rules For The Jobsite

Image credits: construction.fail

There are many, many ways you can injure yourself at work, but the National Safety Council (NSC) found that there are seven common safety hazards that are spotted over and over again.

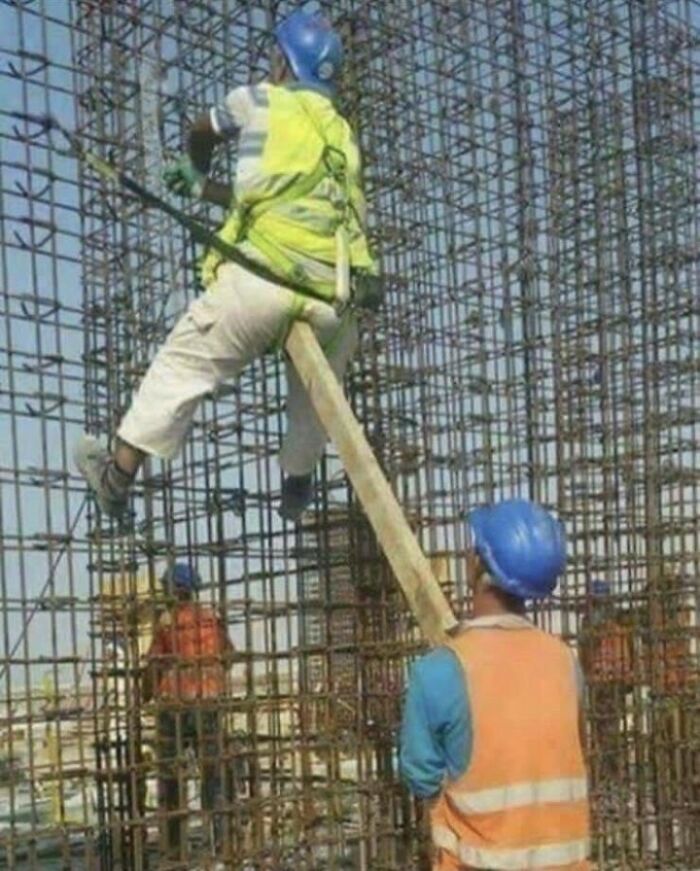

It shouldn’t be a surprise that working at height is at the top of the list. Issues related to scaffolding and ladders are among the most frequently cited violations. NSC consultant JoAnn Dankert said hazards associated with working at height can originate from a lack of understanding. Employers may not know they have to provide fall protection or the fall protection gear may not be worn properly or not hooked up to anything. Some employers don’t even have a written fall protection procedure or process.

#3 This Will Be The New Way To Get Around All Job Sites

Image credits: construction.fail

#4 Nothing To See Here Folks

Image credits: construction.fail

#5 The Most Appropriate Anchor Point

Image credits: construction.fail

Another common issue is poor housekeeping. Imagine there’s a pile of things blocking the emergency exits or crumbling ceilings and leaking water that no one takes care of; all of this can contribute to slips and falls. Things like that just invite trouble and increase the risk of injury.

Not to mention other threats like allergens, biological agents, and chemicals. According to another NSC consultant, Rachel Harrington, when an organization purchases and uses chemicals, it needs to have a control system and know why they were ordered and when to use them.

#6 Bobs Solution When The Trench Is Just A Little Too Deep For The Bucket

Image credits: construction.fail

#7 Is This Any Better Bob?

Image credits: construction.fail

#8 Bob Doesn’t Do Just One Safety Infraction, He Does Many

Image credits: construction.fail

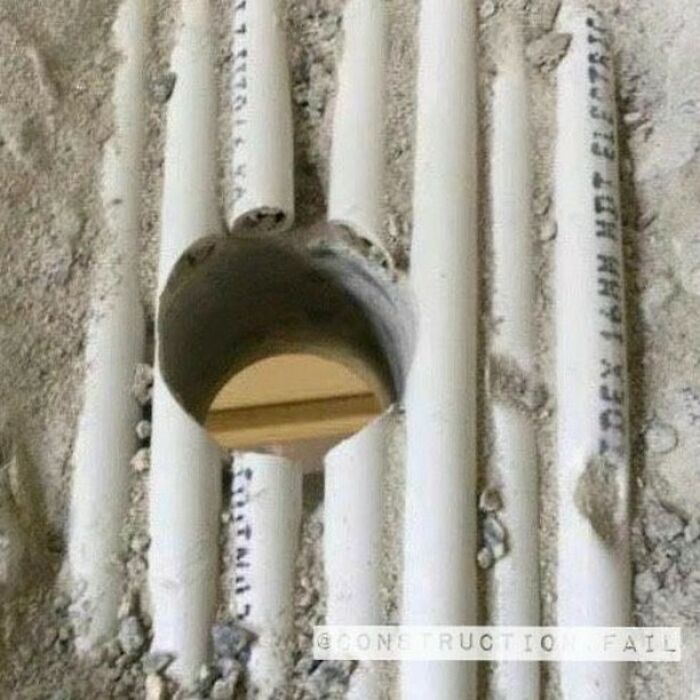

#9 When Electrician Bob Runs His Conduit Where You Told Him Not To

Image credits: construction.fail

The most important things when it comes to preventing slips, trips, and falls are making sure that the flooring is intact, spills are cleaned and blind spots are covered with warning signs or mirrors.

Also, there’s always the issue of fire hazards. Employees should make sure that flammable materials are always kept in designated locations.

#10 Why Bother Getting A Lift When You Have Three Ladders And Some Lumber Right Bob

Image credits: construction.fail

#11 This Has Been Posted All Over

Image credits: construction.fail

#12 Bob Hold On I’ll Give You A Hand Out

Image credits: construction.fail

Next, we have electrical – extension cords. Dankert often witnesses “daisy-chaining” – using multiple extension cords or power strips for a device. At one manufacturing facility Dankert visited, she saw as many as five extension cords chained together.

“It was almost like Christmas tree lights,” she said. “All you really saw were all these electrical cords everywhere.”

#13 The Backside Of The Rebar Really Needed To Be Inspected Didn’t It Bob

Image credits: construction.fail

#14 Don’t Worry Guys.the Taper Will Fix It Haha

Image credits: construction.fail

#15 Builder Bob Hiding From Monday’s!

Image credits: construction.fail

Although extension cords can be useful for temporarily supplying power for certain operations, the key word is “temporarily.” When a cord is used for several weeks or months, Dankert said, OSHA doesn’t consider the use temporary. This opens the door for a violation.

Beyond that, extension cords lying on the ground for extended periods of time are a trip hazard. They also can be subject to traffic abuse if run over by forklifts or feet, which can wear down insulation and create shock hazards. When cords are daisy-chained, they can easily overdraw electricity from the circuits, causing the wires to heat up and potentially result in a fire.

#16 Real Heroes Don’t Wear Capes, Real Heroes Strap Loads To The Roof And Pray

Image credits: construction.fail

#17 Bob Quick The Safety Inspector Is Here, Get Rid Of The Lift

Image credits: construction.fail

#18 Yea Bob We’ve Got The Same Feeling About This Week As Well

Image credits: construction.fail

#19 Just Use The Hazard Notice Board Bob, It’ll Be Fine

Image credits: construction.fail

Forklifts are another common problem. More specifically, trying to work them quickly. When workers are under pressure, they’re searching for shortcuts, which include driving with too large of a load or driving distracted. The end result may be hitting a rack, damaging a wall or product, or even injuring a co-worker.

#20 Who Needs Scaffolding For Stairs When You Have Bob Ingenuity

Image credits: construction.fail

#21 Hey Bob Just Drop Her Right Over There

Image credits: construction.fail

#22 When The Electrician Is Using The Lift Bob Improvises

Image credits: construction.fail

Moving on, lockout/tagout. These procedures can help prevent serious injuries, but only if they are followed.

Violation of lockout/tagout procedures often boils down to three reasons:

- Complacency;

- A rush to finish the work;

- Being unfamiliar with the equipment.

A lot of organizations have the best procedures in place, but it’s the implementation that fails.

#23 I Feel Like Bob Is Starting To Tell A Story

Image credits: construction.fail

#24 It’s Ladder Week At Construction Fails – Pay Attention Osha! When That Top Rung Just Won’t Be Enough

Image credits: construction.fail

#25 Hey Bob Can You Go Grab The Bucket Off The Top Shelf?

Image credits: construction.fail

Chemicals can be expensive, and workers in some industries may never know when they’ll need to use them, but this kind of thinking can lead to serious hazards. Before you know it, you have all these materials no one wants or needs.

It may be easy to overlook a small, 5-gram bottle, but those 5 grams can become unstable over time. When an organization purchases and uses chemicals, it needs to have a control system. It needs to know what the chemicals are for and why they were ordered.

Another potential hazard is transferring them from one container to another. Even if employees feel comfortable doing it and have performed these tasks for years, the containers must be labeled as required under the hazcom standard.

#26 Nailed It

Image credits: construction.fail

#27 Bob Doesn’t Have An Operators License So He Hand Digs

Image credits: construction.fail

#28 Bob You Remember To Put Up The Pylons Right?

Image credits: construction.fail

Finally, we come to confined spaces. They can present a number of hazards, and many tragedies involving confined spaces have occurred because an employer didn’t issue a permit or failed to carry out a risk assessment.

If the risk assessment and permit process are done correctly, and all steps are followed, employers shouldn’t have a problem.

#29 Bob Just Doesn’t Have Time To Rent Scissor Lifts

Image credits: construction.fail

#30 I Got You Bob

Image credits: construction.fail

The NSC consultants stress that the seven hazards presented are by no means an exhaustive list. And as you can see in the pictures, many other hazards can exist at a worksite, and spotting them requires vigilance.

Go to Source

Author: Gabija Palšytė